Robots Are Forever: How A Robot Diamond Cutter Could Change A Market Already Disrupted By Lab-Grown Diamonds

January 3, 2025 by David Edwards

About six years ago, the Scientific and Technical Research Center for Diamonds , in Antwerp, Belgium, demonstrated a highly sophisticated robotic system that can automatically cut or polish diamonds in a fraction of the time it takes the most experienced human diamond cutter to do it by hand –“10 to 20 times faster”, according to its makers.

Called the“Fenix” robot, the system is incredibly well designed and it's no surprise that it generated a lot of interest. So much so that a company called HS Technology, based in the United States, ended up acquiring the entire organisation – it bought the Scientific and Technical Research Center for Diamonds.

Not much was heard about Fenix after that, but the latest is that HD Blueprint , a company specialising in the development of diamond cutting and polishing technologies, now owns the company and machine.

In the secretive world of diamonds, not much information is readily available about what's going on, but Fenix has always had the potential to cause huge disruption – both in terms of challenging the current technologies being used for cutting diamonds, as well as the tens of thousands of human workers who currently work in what is a global industry.

Looking at HB Blueprint's website reveals that the company uses its technology“in-house”, mainly for processing its own or its clients' diamonds, I suppose.

On its“about” page it says:“Most of our technology is used in-house, ensuring our state-of-art ecosystem utilises the most advanced, cutting-edge technologies to track, analyze, saw, cut, laser, and polish our diamonds.”

The company appears to have split the Fenix system into its constituent parts – visual analysis, planning of cuts, actual cutting, and so on – and treats them as separate technologies. None of which are made available to outside companies, it appears.

Which is bad luck for us because we wanted to know how a robot would disrupt the diamond cutting industry globally. Nonetheless, let's take a look at the diamond industry as a whole and learn about the technologies being used to cut and polish what is regarded as the most valuable gem ever discovered in the history of humanity.

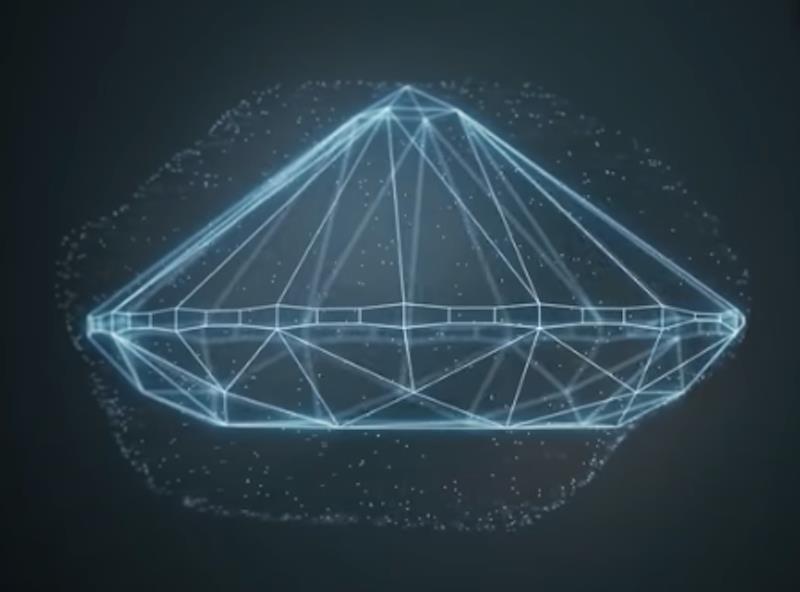

Shine on, you crazy diamondDiamonds have captivated humanity for centuries with their brilliance, durability, and symbolism. Yet, the transformation of rough diamonds into dazzling gems involves precise and complex processes, which have been revolutionised by advancements in technology.

This article delves into the cutting-edge technologies reshaping diamond cutting, focusing on the diamond-cutting robot developed by the Scientific and Technical Research Center for Diamonds (recently acquired by HS Security), and explores trends in the global diamond market and the rise of lab-grown diamonds.

Diamond-cutting revolutionThe Scientific and Technical Research Center for Diamonds in Antwerp has long been a hub of innovation in the diamond industry. One of its crowning achievements is the development of a diamond-cutting robot.

This robotic system, called Fenix, was designed to optimise precision and efficiency. It uses advanced algorithms and machine learning to analyse the structure of each rough diamond, determining the best cuts to maximise yield and value.

This robot integrates:

-

High-resolution imaging : To create a detailed 3D map of the diamond's internal structure.

AI-driven optimisation : To calculate optimal cutting strategies.

Laser precision cutting : Ensuring minimal waste and exceptional accuracy.

With the acquisition of this institution by HS Technology, and then by HB Blueprint, it's possible that further investments will enhance the robot's capabilities, setting new benchmarks for automation in the diamond industry.

Other technologies in diamond cutting

In addition to robotics, several other technologies play a pivotal role in modern diamond cutting:

1. CNC machines (Computer Numerical Control)

These machines provide automated precision for cutting and shaping diamonds.

CNC systems ensure consistent quality by eliminating human errors.

2. Laser cutting

Lasers are widely used for their ability to make precise cuts with minimal thermal damage.

They allow for intricate designs and are crucial in creating fancy-cut diamonds.

3. Water jet cutting

Although less common, water jets are sometimes used for specific types of diamond processing where thermal effects must be avoided entirely.

4. Traditional hand cutting

Still employed for high-value diamonds, relying on the expertise of master cutters for intricate or custom designs.

The global diamond market has experienced fluctuating dynamics over the past five years. Here are some highlights:

-

Pandemic-driven boom : During the Covid-19 pandemic, diamond sales surged as consumers directed discretionary spending toward luxury goods.

Post-pandemic decline : In the past two years, however, sales have slowed due to economic uncertainty and changing consumer preferences.

Market size : As of 2024, the global diamond market is valued at approximately $84 billion, with a compound annual growth rate of 3 percent from 2018 to 2023.

McKinsey has done an interesting report about the diamond industry being at an“inflection point” which would be worth looking at if you're interested in this market.

Major trendsOne of the reasons why McKinsey probably thinks the diamond industry is at an inflection point is because of lab-grown diamonds.“Cultured” pearls are not actually lab grown – they are natural pearls but cultivated by humans in controlled conditions, but that practice basically killed the whole business of humans going pearl diving in the Red Sea or wherever.

But while they may not be lab grown, cultured pearls are probably worth considering when projecting what may happen in the global diamond market. Anyway, here is a list of challenges facing the traditional diamond industry:

-

Lab-grown diamonds : Increasing adoption of synthetic diamonds, particularly among younger consumers.

Sustainability : A shift towards ethically sourced and environmentally sustainable diamonds.

E-commerce growth : Online platforms are capturing a significant share of the diamond retail market.

Lab-grown diamonds, chemically and optically identical to natural diamonds, have gained considerable traction. Their affordability and ethical appeal make them a popular choice for eco-conscious and budget-savvy consumers.

Impact on natural diamonds

Lab-grown diamonds are priced 20-40 percent lower than natural ones, putting downward pressure on the latter's market.

Manufacturers are increasingly adopting these alternatives for industrial applications due to cost advantages.

Market share

Lab-grown diamonds accounted for an estimated 10 percent of the global diamond market in 2023, with rapid growth projected.

Despite technological advancements, human diamond cutters remain vital, particularly for bespoke and high-value pieces. An estimated 1 million diamond cutters are employed worldwide, predominantly in the following centres:

-

Antwerp, Belgium : Regarded as the“diamond capital of the world”, Antwerp specialises in high-value and bespoke cuts.

Surat, India : The largest diamond cutting hub, processing over 90 percent of the world's diamonds by volume.

The integration of robotics and advanced technologies will continue to reshape the diamond industry, enhancing efficiency and sustainability.

However, the role of skilled artisans and the growing influence of lab-grown diamonds underscore the nature of the competition at the heart of this market.

As technology and consumer preferences evolve, so too will the diamond industry's landscape, balancing tradition with innovation.

Perhaps the diamond market will go the way of the watch market, with the mass market on the one side, and the premium, super-expensive market on the other.

Legal Disclaimer:

MENAFN provides the

information “as is” without warranty of any kind. We do not accept

any responsibility or liability for the accuracy, content, images,

videos, licenses, completeness, legality, or reliability of the information

contained in this article. If you have any complaints or copyright

issues related to this article, kindly contact the provider above.

Comments

No comment