Aluminum Composite Panel Market Share Sees Growth As Sustainable Building Materials Gain Traction Market Trends & Business Updates

- Share Tweet Pin LinkedIn Email

The Aluminum Composite Panel Market offers immense growth opportunities, supported by increasing demand in construction, automotive, and advertisement applications. With advancements in technology and a shift towards sustainability, the industry is poised for significant evolution. Stakeholders, including manufacturers and investors, should leverage these trends to capitalize on the burgeoning market potential from 2023 to 2032.

The global aluminum composite panel (ACP) market has emerged as a dynamic sector with substantial growth potential, driven by the material's versatile applications and its demand across multiple industries. The report provides an in-depth analysis of market trends, segmented by product type, application, and geographic regions, projecting significant growth from 2023 to 2032.

Get more information on“Global Aluminum Composite Panel Market Research Report” by requesting FREE Sample Copy at

Market Overview

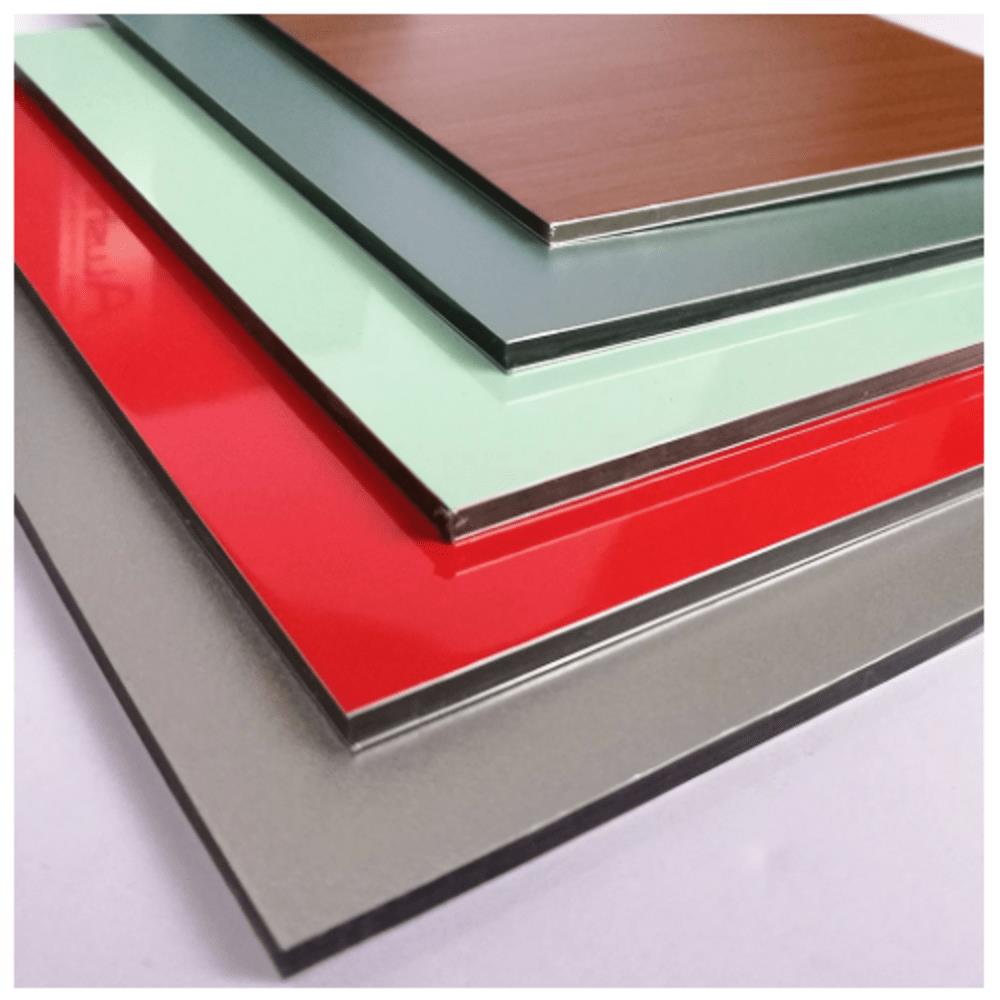

Aluminum composite panels are lightweight, durable, and aesthetically versatile materials widely used in construction, automotive, advertising, and transportation industries. Their features, such as fire resistance, weatherproofing, and easy installation, make them a preferred choice over traditional materials.

The market is expected to grow significantly due to rising construction activities, urbanization, and increasing demand for sustainable and energy-efficient materials.

Market Segmentation

By Product Type-

PVF (Polyvinylidene Fluoride): Renowned for excellent weather resistance, making it ideal for outdoor applications.

Polyester: Economical and suitable for moderate weather conditions.

Laminating Coatings: Offers durability and resistance against corrosion, enhancing the panel's lifespan.

Oxide Film: Provides superior scratch resistance and thermal insulation.

Others: Includes nano-coated panels and fire-resistant variants, catering to specialized needs.

The PVF segment dominates the market due to its high durability and growing adoption in exterior building applications.

By Application-

Construction: The largest segment, driven by the increasing need for modern and sustainable buildings. ACPs are extensively used for cladding, ceilings, partitions, and interior design.

Automotive: Used for lightweight body panels, enhancing vehicle fuel efficiency.

Advertisement Boards: ACPs offer smooth surfaces for high-quality printing, ensuring vivid and durable advertising displays.

Railways: Lightweight and corrosion-resistant panels are ideal for train interiors and exteriors.

Others: Includes marine and industrial applications.

The construction sector remains the primary revenue generator, supported by global urbanization trends and infrastructure development.

Regional Insights

North America:-

High demand from the construction and automotive industries.

Stringent building codes promoting fire-resistant materials drive the adoption of ACPs.

-

Focus on sustainable materials and green buildings boosts market growth.

Significant demand in the advertisement boards segment.

-

The largest market, driven by rapid urbanization, infrastructure projects, and industrialization in countries like China and India.

Growing automotive and construction industries further bolster the market.

-

Emerging markets with rising investments in construction and infrastructure.

Increased adoption of lightweight and cost-effective materials.

Browse Global Aluminum Composite Panel Market Research Report with detailed TOC at

Market Dynamics

Drivers

-

Urbanization and Infrastructure Development: The global shift toward urban living and smart cities propels ACP demand.

Sustainability Focus: Increasing emphasis on eco-friendly materials drives innovation in ACP production.

Aesthetic Appeal: Customization options for colors, textures, and finishes support usage across diverse applications.

Challenges

-

Raw Material Price Fluctuations: Volatility in aluminum prices impacts production costs.

Environmental Concerns: Traditional ACPs contribute to waste, pushing manufacturers toward recyclable and sustainable solutions.

Opportunities

-

Innovations in fire-resistant and nano-coated panels open new market avenues.

Expanding applications in railways, marine, and renewable energy sectors.

Market Trends

-

Fire-Resistant Panels: Stricter safety regulations spur demand for panels with enhanced fire resistance.

Eco-Friendly Solutions: Manufacturers focus on reducing carbon footprints through recyclable ACPs.

Technological Advancements: Integration of smart technologies in ACPs for energy efficiency and enhanced functionality.

Forecast and Competitive Landscape

The global aluminum composite panel market is expected to achieve a compound annual growth rate (CAGR) of approximately 6-7% during the forecast period. Key players driving the market include Alubond USA, Mitsubishi Chemical Corporation, Alpolic Materials, 3A Composites, and Arconic Corporation , among others. Strategies such as mergers, acquisitions, and product innovations remain pivotal for market leadership.

Legal Disclaimer:

MENAFN provides the

information “as is” without warranty of any kind. We do not accept

any responsibility or liability for the accuracy, content, images,

videos, licenses, completeness, legality, or reliability of the information

contained in this article. If you have any complaints or copyright

issues related to this article, kindly contact the provider above.

Comments

No comment