Magnetic Gorilla Guard Helps Construction Safety Engineers Address Swing Radius Hazards'

VANCOUVER, Wash., Aug. 2, 2022 /PRNewswire/ -- Pacific Cascade Corporation (PCC), ParkingZone, and the newly introduced Magnetic Gorilla Guard is reducing on-site construction safety hazards. Part of the Gorilla Post Magnetic Mounting System, the Magnetic Gorilla Guard attaches to mobile heavy equipment to warn co-workers of possible crushing risk.

Continue Reading

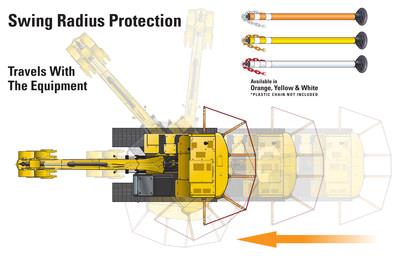

Magnetic Gorilla Guards are mounted directly onto the superstructure to indicate Swing Radius Hazards.

The standard for protection against pinch/crush hazards by the superstructure travels with the equipment and reduces labor costs.

The Occupational Safety and Health Administration (OSHA) enforces standards for a safe and healthful working environment. OSHA has regulations regarding work area control around Cranes & Derricks in Construction addressing Swing Radius Hazards. The requirements apply where there are accessible areas in which the equipment's rotating superstructure poses a reasonably foreseeable risk of pinching/crushing an employee against another part of the equipment or another object. To prevent employees from entering these hazard areas, the employer must erect and maintain control lines, railings or similar barriers to mark the boundaries of the Swing/Crush Hazard Zone. In simple terms, a rotating crane can cause a lot of harm to a person standing too close.

Normally, construction companies must indicate the counter swing area by placing delineators or barricades on the ground around the crane so workers do not stand in, or approach the pinch point hazard areas to satisfy OSHA regulations.

Malcolm Drilling is one of the largest specialty drilling and deep foundation contractors in North America. 'We do not care for this method at Malcolm Drilling, our cranes and drills are constantly on the move on a job site,' explained Nick Noradoun, Safety and Logistics Superintendent from the Hayward, CA Office, 'the Gorilla Guard allows us to change locations without having to remove and reposition the warning barricades. It's a time and labor savings.' Additionally, Noradoun stated, 'OSHA had come out to the job site and was satisfied that we'd covered all the requirements of the Swing Radius Hazards regulations.'

'This is truly a unique solution and construction companies and operators should check with local OSHA regulations for deployment placement, and how they are linked together,' suggests Lyle Peters, Director of U.S. Sales for the Gorilla Post System.

According to Bill Sloniker, WA State Dept. of L&I – Crane Certification Program Supervisor / Crane Technical Specialist, the Magnetic Gorilla Guard satisfies the WAC 296-155-53400 General Requirements for work area control and swing radius hazards. When applied in the manner of the accompanying photos meet the standard for protection against pinch/crush hazards by the superstructure. In addition, employers must train their employees how to recognize the pinch/crush hazard areas.

Magnetic Gorilla Guards are mounted directly onto the superstructure. These guards use neodymium magnets that have a magnetic pull of 380 psi, and have a 360° swivel, pivoting spring base which flexes if it hits an employee or object. To remove the guard, there is an ergonomic removal tool that breaks the industrial-strength coupling allowing quick removal.

'Safety' Steve Summers, Safety Manager for Northbank Civil and Marine states, 'it's a very practical solution to an ongoing problem, well built, durable and the magnets are very strong . . . I definitely recommend getting the tool to assist pulling the magnets off.' Northbank Civil and Marine primarily focuses on marine, heavy civil and industrial construction projects throughout the western US.

'It's thinking 'outside-the-box', our clients are using the Gorilla Posts for applications we didn't think of. We have a corporation in Utah who has a mining operation and places Gorilla Posts on the walls of their mine to warn large-material vehicle drivers when they are getting too close to the mine walls. They found the Gorilla Posts were instrumental in reducing their costs to replacing vehicle mirrors,' Peters added.

PCC is the developer of the Gorilla Post Magnetic System with numerous domestic and international patents.

CONTACT PERSON:Lyle PetersDirector of U.S. Sales for the Gorilla Post SystemPacific Cascade Corporation14208 N.W. 3rd Court • Suite 200Vancouver, WA 986851-800-292-7275 ext. 207[email protected] ParkingZone.com

ABOUT PACIFIC CASCADE CORPORATION AND PARKINGZONESince 1987, PCC and ParkingZone are proud supplying numerous industries with the best products available. Call us at 1-800-292-7275, chat at our website, or message us online. We are available from 8am to 5pm PST, Monday through Friday.

SOURCE ParkingZone

Legal Disclaimer:

MENAFN provides the information “as is” without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the provider above.

Comments

No comment