ABB Updates Vision For The All-Electric Mine With New Roadmap To Zero-Emission Operations

November 11, 2025 by David Edwards

ABB has unveiled its refreshed vision for the“all-electric mine”, with the second edition of its whitepaper titled, Building the all-electric mine: Starting small, thinking big.

Published four years after the launch of the first edition, ABB's updated paper builds on the company's decades-long legacy in industrial electrification.

Mining contributes up to 7 percent of global greenhouse gas emissions, however, statistics from ABB's Mining's Moment report released just a year ago in October 2024, revealed that 30 percent of industry leaders are behind on their 2030 decarbonization goals.

The whitepaper expands on these insights, emphasizing the importance of ABB's vision to accelerate our progress towards all-electric mines, including:

Electrifying operations, such as with haul truck trolley assist infrastructure, can reduce carbon emissions by up to 90 percent.

As such, in October 2024, 42 percent of mining companies were planning to decarbonize haulage fleets by 2026; 68 percent said they will electrify at least 25 percent of fleet by 2030.

More than two-thirds (68 percent) see technology including electrification as a driver for attracting Gen Z talent and tackling the aging workforce.

Mining leaders are on board with the change: More than half (53 percent) of mining companies were expect a significant or complete transformation of their mining operations by 2030.

Since 2021, ABB has conducted 26 eMine studies across 9 countries with global mining companies to understand the practical challenges and opportunities of fleet electrification.

With four years of real progress and innovation, the second edition of the whitepaper outlines how mining operations can take practical, performance-focused steps toward electrification and more sustainable mining today.

Drawing from industry insights and ABB's own technology roadmap, it breaks down the transformation into short-term manageable projects designed to support operational KPIs while laying the foundation for zero-emission mining.

The updated whitepaper outlines why action is urgent, but also possible. Today's technology can significantly cut emissions and operating costs, with many commercially available solutions already proven in the field, such as electric loading, haulage and conveying systems.

ABB's analysis also found that miners are open to adopting new technologies – with 68 percent planning to electrify at least a quarter of their fleets by 2030 – but often prefer tested, proven tools.

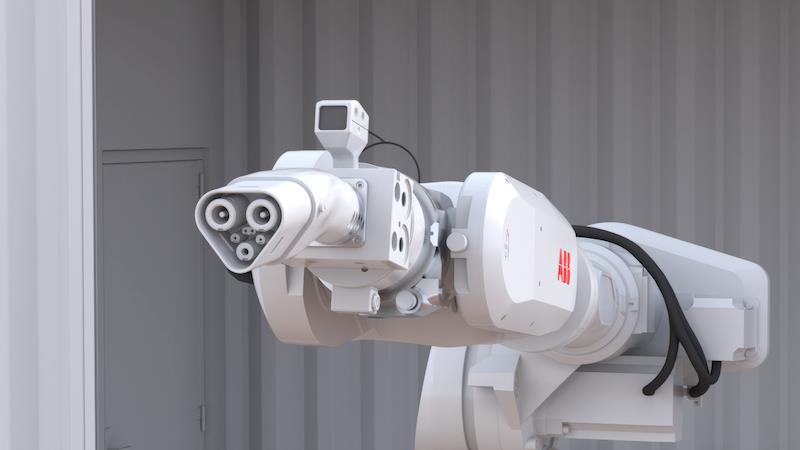

To meet this need, ABB encourages industry players to pilot emerging solutions and collaborate on developing the next wave of electrification technologies. One such innovation is ABB's eMine Robot Automated Connection Device (ACD), an interoperable, fully automated, high-power charging solution for electric mining trucks.

Tested in harsh environments like Boliden's Aitik site in Northern Sweden, the Robot ACD enables fast, safe and hands-free connections while supporting a wide range of fleet interfaces, vendor connection mechanisms, and evolving industry standards.

Björn Jonsson, business line manager for mining and materials, ABB's Process Industries division, says:“Full mine electrification won't happen overnight, but four years after the launch of ABB eMine, we're glad to see progress being made.

“ABB pilot projects provide the blueprint for building confidence and momentum for industry transformation. Now it's time to scale up.

“At ABB, we're helping our partners navigate this transition with low-risk, phased steps that align with technology readiness, fleet and infrastructure cycles, and business goals. It's a collaborative journey, and we're walking it together.”

The latest edition of the whitepaper also responds to common concerns around disruption, capital investment and infrastructure.

Most importantly, it reaffirms ABB's commitment to partnership, offering customers a roadmap to electrification that starts small but builds to industry-scale transformation. This is fueled by automation, digital integration and a shared commitment to sustainable performance.

What is an all-electric mine?An all-electric mine is a mining operation that has transitioned away from fossil fuels to run its equipment and processes, using electricity from renewable sources and battery-powered machinery.

These mines aim to eliminate scope 1 (vehicles and so on) and 2 (energy usage and so on) carbon emissions, lower operating costs, and improve performance by electrifying everything from heavy-duty vehicles to stationary equipment.

Key characteristics of an all-electric mine:

-

Electrified equipment: All mining vehicles, such as haul trucks and loaders, are battery-electric or hybrid-electric.

Renewable energy: The operation is powered by a clean energy grid, often supplemented by energy storage systems, to ensure it is fully powered by fossil-free sources.

Infrastructure changes: Significant updates to the energy supply chain infrastructure are required, which includes installing charging and power systems in remote locations.

Digital integration: Advanced digital systems are integrated with electrification to optimize operations and enhance productivity from the mine to the port or market.

Environmental benefits: The primary goal is to achieve zero-carbon operations, which significantly reduces greenhouse gas emissions and air pollution from particulates.

Economic benefits: Electrification can lead to lower operating costs due to reduced fuel consumption and maintenance requirements for diesel engines.

Legal Disclaimer:

MENAFN provides the

information “as is” without warranty of any kind. We do not accept

any responsibility or liability for the accuracy, content, images,

videos, licenses, completeness, legality, or reliability of the information

contained in this article. If you have any complaints or copyright

issues related to this article, kindly contact the provider above.

Comments

No comment