(MENAFN- Newsfile Corp) Third Rig at Eastmain, Mineralised Tonalite at E Zone

HIGHLIGHTS

- Third drill rig on site adding to the two already in operation at Eastmain

- Drilling capacity increased to c.1,500m/week - 38,000m drilled to date, on track to achieve the 2021 plan of 50,000m

- Drilling targeting DHEM conductors down-plunge of A and C Zones and extensions to E Zone

- Over 15,000 samples from 52 drillholes awaiting assays

- New style of mineralisation discovered at E Zone associated with a tonalite intrusion located structurally between the Kotak and Mine trend with visible gold observed

Toronto, Ontario--(Newsfile Corp. - October 20, 2021) - Benz Mining Corp. (TSXV: BZ) (ASX: BNZ) (the Company or Benz ) is pleased to provide an update on its 2021 drilling campaign. The third drill rig, originally booked for September, is now on site at Eastmain and drilling electromagnetic targets down-plunge from the existing resource.

CEO, Xavier Braud, commented: "The third rig we needed to accelerate our drilling program is now in operation at Eastmain. Our current drilling capacity has increased to ~1,500m per week which will see us achieve our original target of 50,000m of drilling this year. We currently have over 15,000 samples awaiting assay results. Turnaround time at the laboratory has been extremely slow especially with the need for metallic screen fire assays. The discovery of a new mineralised system with visible gold at E Zone is also very exciting and we look forward to sharpening our understanding of this new fertile system. Eastmain is still surprising us which augurs very well for the future."

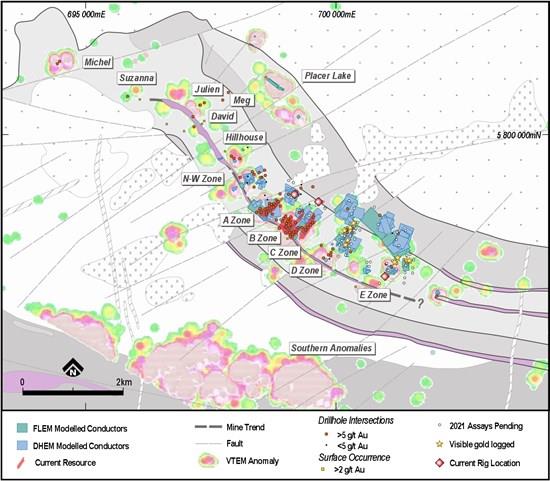

Figure 1: Eastmain Gold Project with 2021 drillholes pending assays, 2021 drilling with logged visible gold, DHEM conductors modelled to date and current drill rig location

To view an enhanced version of Figure 1, please visit:

Figure 2: Map view of the Eastmain Project with historical and current high grade drill results and 2021 drilling pending assays with EM conductors and simplified geology

To view an enhanced version of Figure 2, please visit:

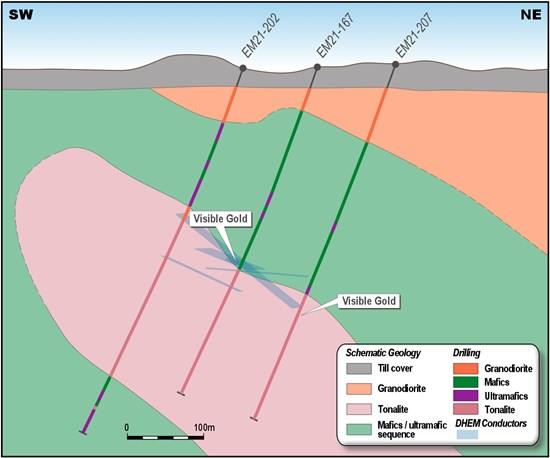

Tonalite Zone discovery

At E Zone, drilling encountered a tonalite intrusion structurally located between the Kotak horizon and the Mine horizon.

This tonalite has a variable thickness over the area.

The tonalite shows numerous zones of alteration with silicification, sericitization and albitisation. Quartz veins are present with associated tourmaline and carbonate.

The tonalite also shows sulphide mineralisation as disseminations in the veins and on their margins. Sulphides include pyrite, pyrrhotite and chalcopyrite with occasional sphalerite and molybdenite. Garnet porphyroblasts are observed in the strongest alteration zones. Sulphide mineralisation coincides broadly with the conductors identified by downhole EM.

Quartz veins with carbonate within the tonalite contain visible gold.

Visible gold was also observed in the upper sheared contact between the tonalite and the overlying alternation of volcanics and ultramafics.

Figure 3: NE-SW Schematic geological cross section showing the newly discovered

mineralised tonalite intrusion at E Zone

To view an enhanced version of Figure 3, please visit:

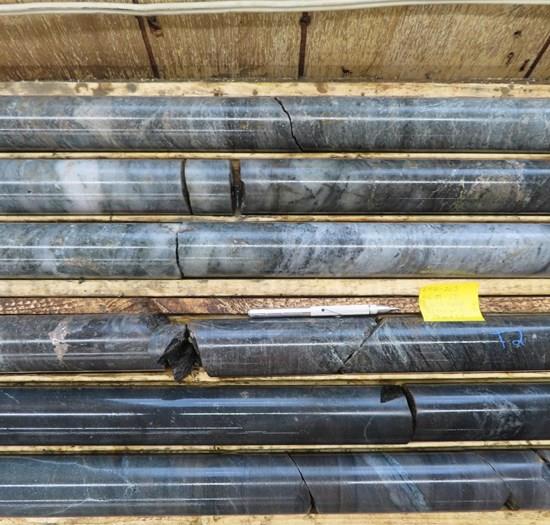

Figure 4: Mineralised tonalite contact with visible gold associated with quartz-pyrrhotite

veining (Hole EM21-167, 278.6m)

To view an enhanced version of Figure 4, please visit:

Figure 5:Mineralised vein is hosted in a moderately biotitized, silicified and albitized tonalite with tourmaline-quartz carbonate veins and local garnet porphyroblasts. (Hole EM21-207, 342.2m)

To view an enhanced version of Figure 5, please visit:

A and C Zones extensions at depth guided by DHEM

Drilling of DHEM conductors down-plunge from A and C Zones show that the mineralised system carries out at depth. The current drilling in those areas follows the same methodology applied by Benz in the last 12 months at Eastmain with 100m step-outs. Whilst this spacing is too wide to establish a resource estimate from the current drilling, it gives the Company a much better understanding of the potential footprint of the deposit before planning infill drilling.

Figure 6: C Zone depth extension (EM21-205, 601.0m)

To view an enhanced version of Figure 6, please visit:

Figure 7: A Zone depth extension, Mine horizon with quartz, pyrrhotite, pyrite and chalcopyrite (EM21-204B, 564.7m)

To view an enhanced version of Figure 7, please visit:

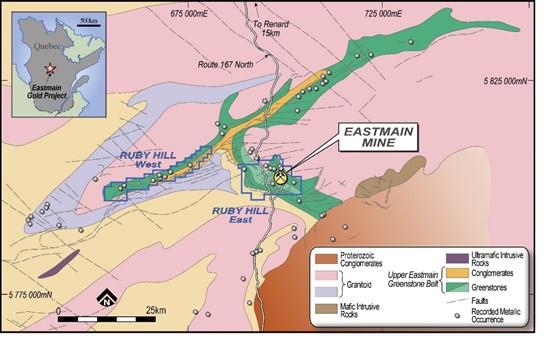

Eastmain Gold Project

The Eastmain Gold Project, situated on the Upper Eastmain Greenstone Belt in Quebec, Canada, currently hosts a NI 43-101 and JORC (2012) compliant resource of 376,000oz at 7.9gpt gold (Indicated: 236,500oz at 8.2gtp gold, Inferred: 139,300oz at 7.5gtp gold). The existing gold mineralisation is associated with 15-20% semi-massive to massive pyrrhotite, pyrite and chalcopyrite in highly deformed and altered rocks making it amenable to detection using electromagnetic techniques. Multiple gold occurrences have been identified by previous explorers over a 10km long zone along strike from the Eastmain Mine with very limited but highly encouraging testing outside the existing resource area. Benz has subsequently identified over 150 DHEM conductors over a strike length of 6km which is open in all directions.

This press release was prepared under supervision and approved by Dr. Danielle Giovenazzo, P.Geo, acting as Benz's qualified person under National Instrument 43-101.

About Benz Mining Corp.

Benz Mining Corp. brings together an experienced team of geoscientists and finance professionals with a focused strategy to acquire and develop mineral projects with an emphasis on safe, low risk jurisdictions favourable to mining development. Benz is earning a 100% interest in the former producing high grade Eastmain gold mine, Ruby Hill West and Ruby Hill East projects in Quebec.

The Eastmain Gold Project is situated within the Upper Eastmain Greenstone Belt in Quebec, Canada and currently hosts a NI 43-101 and JORC (2012) compliant resource of 376,000oz at 7.9gpt gold. The existing gold mineralization is associated with 15-20% semi-massive to massive pyrrhotite, pyrite and chalcopyrite making it amenable to detection by electromagnetics. Several gold mineralization occurrences have been identified by previous explorers over a 10km long zone along strike from the Eastmain Mine with very limited testing outside the existing resource area.

Figure 8: Benz tenure over Upper Eastmain Greenstone Belt simplified geology.

To view an enhanced version of Figure 8, please visit:

On behalf of the Board of Directors of Benz Mining Corp.

Xavier Braud, CEO

For more information please contact:

Paul Fowler

Head of Corporate Development (Canada)

Benz Mining Corp.

Telephone: +1 416 356 8165

Email:

Xavier Braud

CEO, Head of Corporate Development (Aus)

Benz Mining Corp.

Telephone +61 423 237 659

Email:

Forward-Looking Information: Certain statements contained in this news release may constitute "forward-looking information" as such term is used in applicable Canadian securities laws. Forward-looking information is based on plans, expectations and estimates of management at the date the information is provided and is subject to certain factors and assumptions, including, that the Company's financial condition and development plans do not change as a result of unforeseen events and that the Company obtains regulatory approval. Forward-looking information is subject to a variety of risks and uncertainties and other factors that could cause plans, estimates and actual results to vary materially from those projected in such forward-looking information. Factors that could cause the forward-looking information in this news release to change or to be inaccurate include, but are not limited to, the risk that any of the assumptions referred to prove not to be valid or reliable, that occurrences such as those referred to above are realized and result in delays, or cessation in planned work, that the Company's financial condition and development plans change, and delays in regulatory approval, as well as the other risks and uncertainties applicable to the Company as set forth in the Company's continuous disclosure filings filed under the Company's profile at . The Company undertakes no obligation to update these forward-looking statements, other than as required by applicable law.

NEITHER THE TSX VENTURE EXCHANGE NOR ITS REGULATION SERVICES PROVIDER (AS THAT TERM IS DEFINED IN THE POLICIES OF THE TSX VENTURE EXCHANGE) ACCEPTS RESPONSIBILITY FOR THE ACCURACY OR ADEQUACY OF THIS RELEASE.

Competent Person's Statements: The information in this report that relates to Exploration Results is based on and fairly represents information and supporting information compiled by Mr Xavier Braud, who is a member of the Australian Institute of Geoscientists (AIG membership ID:6963). Mr Braud is a consultant to the Company and has sufficient experience in the style of mineralization and type of deposits under consideration and qualifies as a Competent Person as defined in the 2012 edition of the "Australasian Code for Reporting of Exploration Results, Mineral Resources and Ore Reserves". Mr Braud holds securities in Benz Mining Corp and consents to the inclusion of all technical statements based on his information in the form and context in which they appear.

The information in this announcement that relates to the Inferred Mineral Resource was first reported under the JORC Code by the Company in its prospectus released to the ASX on 21 December 2020. The Company confirms that it is not aware of any new information or data that materially affects the information included in the original market announcement and confirms that all material assumptions and technical parameters underpinning the estimate continue to apply and have not materially changed. The Company confirms that the form and context in which the Competent Person's findings are presented have not been materially modified from the original market announcement.

Appendix 1: Collar Table 2021 Drilling

| DDH ID | X_NAD83_Z18N | Y_NAD83_Z18N | Elevation | Azimuth (planned) | Azimuth (measured) | Dip planned | Dip (measured) | Planned Depth | Total Drilled length |

| EM21-143 | 698713 | 5798618 | 485.0 | 215 | 215.35 | -56.9 | 56.92 | 550 | 567 |

| EM21-144 | 698568 | 5799058 | 485 | 215 | 215.1 | -75 | 75 | 450 | 477 |

| EM21-145 | 698315 | 5799210 | 487 | 215 | 215.3 | -60 | 60 | 350 | 333 |

| EM21-146 | 698280 | 5799265 | 495 | 215 | 215 | -60 | 60 | 350 | 297 |

| EM21-147 | 698184 | 5799041 | 490 | 220 | 220 | -55 | 55 | 200 | 225 |

| EM21-148 | 698192 | 5799167 | 491 | 220 | 220 | -60 | 55 | 265 | 265 |

| EM21-149 | 698014 | 5799532 | 487 | 217 | 217 | -55 | 54.9 | 220 | 225 |

| EM21-150 | 698182 | 5799743 | 510 | 217 | 217.1 | -55 | 54.9 | 165 | 201 |

| EM21-151 | 698569 | 5798713 | 483 | 216 | 216.19 | -60 | 60.4 | 620 | 657 |

| EM21-152 | 699236 | 5798936 | 508 | 225 | 225 | -75 | 74.9 | 600 | 636 |

| EM21-153 | 699248 | 5798810 | 480 | 225 | 225.3 | -80 | 80.5 | 620 | 619.3 |

| EM21-154 | 699247 | 5799006 | 484 | 225 | 225.16 | -75 | 75 | 610 | 675 |

| EM21-155 | 698518 | 5798790 | 486 | 220 | 219.88 | -60 | 60.4 | 575 | 585 |

| EM21-156 | 698582 | 5799177 | 485 | 215 | 215.04 | -75 | 75.3 | 450 | 507 |

| EM21-157 | 698434 | 5799154 | 485 | 240 | 239.9 | -60 | 58 | 450 | 471 |

| EM21-158 | 698405 | 5799250 | 483 | 245 | 249 | -60 | 59 | 600 | 648 |

| EM21-159 | 698520 | 5799290 | 484 | 245 | 244.5 | -65 | -64.9 | 450 | 450 |

| EM21-160 | 700655 | 5797357 | 503 | 215 | 214.66 | -70 | -70.4 | 450 | 477 |

| EM21-161 | 701002 | 5797424 | 499 | 215 | 214.9 | -60 | -60.2 | 300 | 351 |

| EM21-162 | 700174 | 5798070 | 488 | 210 | 210.4 | -65 | -65.3 | 550 | 651 |

| EM21-163 | 701190 | 5797310 | 509 | 215 | 215.3 | -60 | -60 | 300 | 201 |

| EM21-164 | 701030 | 5797282 | 524 | 210 | 210.4 | -60 | -60.2 | 200 | 273 |

| EM21-165 | 700394 | 5798111 | 487 | 210 |

| -74 | -73.9 | 800 | 783 |

| EM21-166 | 701160 | 5797442 | 494 | 215 | 214.9 | -60 | -60.6 | 380 | 411 |

| EM21-167 | 701401 | 5797480 | 503 | 180 | 180.1 | -70 | -70.2 | 360 | 468 |

| EM21-168 | 700280 | 5798134 | 485 | 210 | 210.3 | -75 | -75 | 680 | 687 |

| EM21-169 | 701246 | 5797779 | 490 | 210 | 209.6 | -75 | -74.6 | 450 | 621 |

| EM21-170 | 700276 | 5797965 | 490 | 210 | 210.3 | -70 | -70.4 | 600 | 636 |

| EM21-171 | 700171 | 5797963 | 489 | 210 | 210 | -70 | -70.3 | 525 | 567 |

| EM21-172 | 700605 | 5797443 | 495 | 210 | 209.9 | -60 | -60 | 450 | 453 |

| EM21-173 | 700297 | 5797805 | 492 | 210 | 204.3 | -70 | -71 | 460 | 463 |

| EM21-174 | 701371 | 5798073 | 484 | 210 | 209.65 | -65 | -65.3 | 800 | 781.45 |

| EM21-175 | 700226 | 5797876 | 487 | 206 | 207.71 | -70 | -70 | 550 | 573 |

| EM21-176 | 701210 | 5798045 | 483 | 213 | 212.8 | -67 | -67 | 610 | 624 |

| EM21-177 | 700114 | 5797875 | 486 | 210 | 209.9 | -70 | -70.1 | 465 | 471 |

| EM21-178 | 700263 | 5798666 | 481 | 215 | 215.3 | -65 | -65 | 600 | 603 |

| EM21-179 | 700062 | 5797789 | 485 | 210 | 209.9 | -70 | -70.1 | 400 | 444 |

| EM21-180 | 700357 | 5798529 | 482 | 210 | 210.1 | -70 | -70.5 | 650 | 648 |

| EM21-181 | 700181 | 5797790 | 487 | 210 | 209.9 | -65 | -65.2 | 490 | 486 |

| EM21-182 | 700341 | 5798224 | 484 | 210 | 209.9 | -75 | -75.2 | 700 | 780 |

| EM21-183 | 700080 | 5798025 | 485 | 210 | 209.8 | 68 | -67 | 600 | 669 |

| EM21-184 | 700368 | 5797902 | 491 | 210 | 210.2 | -70 | -70.1 | 600 | 573 |

| EM21-185 | 700305 | 5798405 | 486 | 210 | 209.47 | -70 | -70.02 | 800 | 804 |

| EM21-186 | 700262 | 5797716 | 494 | 210 | 209.5 | -70 | -70.1 | 420 | 474 |

| EM21-187 | 700428 | 5798232 | 487 | 210 | 205.65 | -75 | -75.2 | 780 | 831 |

| EM21-188 | 700188 | 5797587 | 492 | 210 |

| -70 | -70.1 | 380 | 342 |

| EM21-189 | 700039 | 5797566 | 495 | 210 | 209.45 | -70 | -69.94 | 350 | 309 |

| EM21-190 | 700675 | 5797450 | 497 | 210 | 210.7 | -65 | -65.88 | 450 | 474 |

| EM21-191 | 700474 | 5798085 | 492 | 210 | 208.3 | -70 | -69.83 | 680 | 696 |

| EM21-192 | 701121 | 5797475 | 504 | 215 | 215 | -60 | -59.9 | 380 | 429 |

| EM21-193 | 701204 | 5797420 | 494 | 215 | 215.2 | -60 | -59.9 | 430 | 420 |

| EM21-194 | 700230 | 5798513 | 490 | 210 | 209.7 | -70 | -70.1 | 800 | 837 |

| EM21-195 | 701352 | 5797496 | 500 | 185 | 184.8 | -70 | -70.1 | 460 | 513 |

| EM21-196 | 701352 | 5797496 | 500 | 215 | 215.4 | -60 | -59.7 | 750 | 750 |

| EM21-197 | 700253 | 5798660 | 479 | 200 | 196.7 | -82 | -83 | 550 | 798 |

| EM21-198 | 701457 | 5797479 | 505 | 185 | 185.4 | -70 | -70.4 | 550 | 591 |

| EM21-199 | 699463 | 5798380 | 480 | 215 | 214.7 | -70 | -69.9 | 650 | 720 |

| EM21-200 | 701470 | 5797599 | 513 | 185 | 184.83 | -70 | -69.9 | 550 | 654 |

| EM21-201 | 699599 | 5798581 | 484 | 210 | 209.6 | -70 | -70 | 750 | 816 |

| EM21-202 | 701389 | 5797381 | 502 | 185 | 184.9 | -70 | -70 | 450 | 528 |

| EM21-203 | 699776 | 5798523 | 483 | 215 | 215.1 | -70 | -70.1 | 670 | 627 |

| EM21-204-B | 699141 | 5799038 | 487 | 215 | 215.4 | -70 | -70.1 | 600 | 711 |

| EM21-205 | 699783 | 5798534 | 482 | 215 | 214.9 | -80 | -79.9 | 700 | 693 |

| EM21-206 | 701545 | 5797486 | 513 | 185 | 185.1 | -70 | -69.9 | 550 | 600 |

| EM21-207 | 701411 | 5797582 | 505 | 185 | N/A | -70 | N/A | 480 | 591 |

| EM21-208 | 699050 | 5799080 | 493 | 215 | 215.89 | -70 | -70.28 | 650 | 588 |

| EM21-209 | 699735 | 5798655 | 482 | 215 | 215.7 | -75 | -75.02 | 650 | 741 |

| EM21-210 | 701222 | 5797541 | 503 | 215 | 214.33 | -65 | -65.51 | 500 | 510 |

| EM21-211 | 699095 | 5798740 | 485 | 220 | 220.91 | -70 | -69.92 | 500 | 471 |

| EM21-212 | 699647 | 5798671 | 477 | 215 | N/A | -70 | N/A | 700 | In progress |

| EM21-213 | 700971 | 5797181 | 531 | 215 | 215.05 | -60 | -60.1 | 300 | In progress |

| EM21-214 | 699169 | 5798821 | 481 | 220 | 219.8 | -70 | -69.8 | 550 | In progress |

Appendix 2: JORC Tables

Section 1 Sampling Techniques and Data

(Criteria in this section apply to all succeeding sections.)

| Criteria | JORC Code explanation | Commentary |

| Sampling techniques | - Nature and quality of sampling (eg cut channels, random chips, or specific specialised industry standard measurement tools appropriate to the minerals under investigation, such as down hole gamma sondes, or handheld XRF instruments, etc). These examples should not be taken as limiting the broad meaning of sampling.

- Include reference to measures taken to ensure sample representivity and the appropriate calibration of any measurement tools or systems used.

- Aspects of the determination of mineralisation that are Material to the Public Report.

- In cases where 'industry standard' work has been done this would be relatively simple (eg 'reverse circulation drilling was used to obtain 1 m samples from which 3 kg was pulverised to produce a 30 g charge for fire assay'). In other cases more explanation may be required, such as where there is coarse gold that has inherent sampling problems. Unusual commodities or mineralisation types (eg submarine nodules) may warrant disclosure of detailed information.

| - NQ size core drilling

- This release does not include analytical results

- Qualitative observations only

|

| Drilling techniques | - Drill type (eg core, reverse circulation, open-hole hammer, rotary air blast, auger, Bangka, sonic, etc) and details (eg core diameter, triple or standard tube, depth of diamond tails, face-sampling bit or other type, whether core is oriented and if so, by what method, etc).

| - Triple tube NQ core drilling.

- Hole depths vary between 201m and 675m

- Core was oriented using downhole orientation tool

|

| Drill sample recovery | - Method of recording and assessing core and chip sample recoveries and results assessed.

- Measures taken to maximise sample recovery and ensure representative nature of the samples.

- Whether a relationship exists between sample recovery and grade and whether sample bias may have occurred due to preferential loss/gain of fine/coarse material.

| - Core recoveries are routinely measured by comparing the length of core recovered against the length of drill rods used and recorded by the drilling contractor.

- For sampled intervals the core is cut in half and half of the core is sent for assays whilst the other half of the core is retained in the core tray for future reference

- Length of core sampled for individual assays is determined by the logging geologist following geological/mineralisation boundaries

- To ensure representativity, no intervals shorter than 50cm are sampled.

|

| Logging | - Whether core and chip samples have been geologically and geotechnically logged to a level of detail to support appropriate Mineral Resource estimation, mining studies and metallurgical studies.

- Whether logging is qualitative or quantitative in nature. Core (or costean, channel, etc) photography.

- The total length and percentage of the relevant intersections logged.

| - Lithology

- Alteration

- Mineralisation

- Mineral species abundance

- Veining

- Structures

- Both qualitative and quantitative logging is routinely conducted

- 100% of the core drilled is logged

|

| Sub-sampling techniques and sample preparation | - If core, whether cut or sawn and whether quarter, half or all core taken.

- If non-core, whether riffled, tube sampled, rotary split, etc and whether sampled wet or dry.

- For all sample types, the nature, quality and appropriateness of the sample preparation technique.

- Quality control procedures adopted for all sub-sampling stages to maximise representivity of samples.

- Measures taken to ensure that the sampling is representative of the in situ material collected, including for instance results for field duplicate/second-half sampling.

- Whether sample sizes are appropriate to the grain size of the material being sampled.

| |

| Quality of assay data and laboratory tests | - The nature, quality and appropriateness of the assaying and laboratory procedures used and whether the technique is considered partial or total.

- For geophysical tools, spectrometers, handheld XRF instruments, etc, the parameters used in determining the analysis including instrument make and model, reading times, calibrations factors applied and their derivation, etc.

- Nature of quality control procedures adopted (eg standards, blanks, duplicates, external laboratory checks) and whether acceptable levels of accuracy (ie lack of bias) and precision have been established.

| - Most samples are submitted for Gold assay by Fire assay and AA (Atomic Absorption) of a 50g pulverized sample with gravimetic determination if >10 g/t.

- Samples where visual observations suggested potential high grade gold and samples with visible gold are routinely submitted for metallic screen fire assays.

- At this stage, no studies have been finalized on the repartition and size of the gold grains in the system, however visual observations of gold grains larger than 0.5mm suggest that fire assays should be considered a partial method at this stage

- Coarse rejects samples will be analysed as duplicates using PhotonAssay

|

| Verification of sampling and assaying | - The verification of significant intersections by either independent or alternative company personnel.

- The use of twinned holes.

- Documentation of primary data, data entry procedures, data verification, data storage (physical and electronic) protocols.

- Discuss any adjustment to assay data.

| - No twinning of holes at this stage

- All sampling protocols have been peer reviewed and all data is stored appropriately

- No adjustments to assay data have taken place.

|

| Location of data points | - Accuracy and quality of surveys used to locate drill holes (collar and down-hole surveys), trenches, mine workings and other locations used in Mineral Resource estimation.

- Specification of the grid system used.

- Quality and adequacy of topographic control.

| - All drillhole locations have been surveyed by handheld GPS with a typical accuracy of +/-4m

- Downhole surveys are conducted using a Reflex Multishot Gyro or an Axis North Seeking Gyro.

- Topographic control is cross-checked with a 2013 LIDAR survey

|

| Data spacing and distribution | - Data spacing for reporting of Exploration Results.

- Whether the data spacing and distribution is sufficient to establish the degree of geological and grade continuity appropriate for the Mineral Resource and Ore Reserve estimation procedure(s) and classifications applied.

- Whether sample compositing has been applied.

| - All drilling conducted by Benz Mining in 2020 and 2021 is wide spaced and exploratory in nature.

- Spacing between drillholes is typically 100m which is insufficient for resource estimation

|

| Orientation of data in relation to geological structure | - Whether the orientation of sampling achieves unbiased sampling of possible structures and the extent to which this is known, considering the deposit type.

- If the relationship between the drilling orientation and the orientation of key mineralised structures is considered to have introduced a sampling bias, this should be assessed and reported if material.

| - Drilling targeted newly identified areas in the geological system. All drilling is oriented towards the SW. As some mineralisation at the project is seemingly dipping toward the NE the orientation of sampling should not introduce a bias in the samples.

|

| Sample security | - The measures taken to ensure sample security.

| - All samples are routinely cut and prepared on site by company employees and contractors.

- Samples bags are sealed and transported to the laboratory directly from the sampling site by specialized transport companies.

|

| Audits or reviews | - The results of any audits or reviews of sampling techniques and data.

| - The Company is constantly reviewing its sampling and assaying policies. No external audit has been conducted at this stage.

|

Section 2 Reporting of Exploration Results

(Criteria listed in the preceding section also apply to this section.)

| Criteria | JORC Code explanation | Commentary |

| Mineral tenement and land tenure status | - Type, reference name/number, location and ownership including agreements or material issues with third parties such as joint ventures, partnerships, overriding royalties, native title interests, historical sites, wilderness or national park and environmental settings.

- The security of the tenure held at the time of reporting along with any known impediments to obtaining a licence to operate in the area.

| - The Eastmain Mine Project comprises 152 contiguous mining claims each with an area of approximately 52.7 ha covering a total of 8,014.36 ha plus one industrial lease permit that are owned by Eastmain Mines Inc., a wholly owned subsidiary of Fury Gold Mines. The claims are numbered 1133433 to 1133583 consecutively plus claim 104458 (Figure 4.2). All of the claims are located within NTS sheet 33A 08.

- The former Mine Lease BM 817 was issued on January 10, 1995 and expired in 2015 after a 20-year term. This former Mine Lease was converted to Industrial Lease 00184710000 on September 1, 2015 and contains all normal surface rights. The former mineral rights for BM 817 are now included in the expanded Claims 1133523, 1133524, 1133525, 1133505, 1133506 and 1133507.

- The claims are 100% held by Fury Gold Mines subject to certain net smelter royalties ("NSR").

- On August 9, 2019, Benz Mining Corp. announced that it has entered into an option agreement with Eastmain Resources Inc. (now Fury Gold Mines) to acquire a 100% interest in the former producing Eastmain Gold Project located in James Bay District, Quebec, for CAD $5,000,000.

- Eastmain Resources would retain a 2% Net Smelter Return royalty in respect of the Project. Benz may, at any time, purchase one half of the NSR Royalty, thereby reducing the NSR Royalty to a 1% net smelter returns royalty, for $1,500,000.

- The Eastmain Mine, as defined by the perimeter of a historic mining lease, is subject to a production royalty net smelter return ("NSR") of 2.3% through production of the next 250,000 oz produced and 2% thereafter. A package of claims surrounding the mine precinct is subject to a production royalty (NSR) of 2% in favor of Goldcorp as a result of their succession to Placer Dome in an agreement dated December 30, 1988 between Placer Dome, MSV Resources Inc. and Northgate Exploration Limited.

- The 152 claims that form the Eastmain Mine Property are all in good standing with an active status.

|

| Exploration done by other parties | - Acknowledgment and appraisal of exploration by other parties.

| - 1930s & 1940s - Prospecting of gossans

- 1950s & 1960s - Riocanex - Exploration of the Upper Eastmain Greenstone Belt

- Mid 1960s - Fort George - Diamond drilling of a gossan zone

- 1696 - Canex Aerial Exploration Ltd & Placer Development Ltd - Airborne magnetic and EM surveys with ground geophysics follow up.

- 1970 - Placer Development Ltd - Seven holes testing an EM anomaly. Discovery of A Zone with 1.5m @ 13.71g/t Au

- 1974 - Nordore - Aerodat airborne AEM survey and Ground geophysics. 3 holes returned anomalous gold values adjacent to B Zone

- 1974 - Inco Uranerz - Airborne geophysical survey over the whole greenstone belt.

- 1981 & 1982 - Placer - Airborne and ground EM, ground magnetics. Drilling of EM anomalies discovered B zone and C zone.

- 1983 to 1985 - Placer - Airborne and ground EM, downhole PEM, 91 holes over A B and C zones.

- 1986 - Placer - 25 holes into A B and C zones

- 1987 &1988 - Placer Dome / MSV JV - Drilling of A, B and C zones

- 1988 to 1994 - MSV Resources - Drilling, surface sampling, trenching, regional exploration, Seismic refraction over ABC Zones,

- 1994 & 1995 - MSV Resources - Mining of 118,356t at 10.58g/t Au and 0.3%Cu, processed at Copper Rand plant in Chibougamau, 40,000oz recovered

- 1997 - MSV Resources- Exploration, mapping, prospecting, trenching.

- 2004 - Campbell Resources - M&I resource calculation for Eastmain Mine.

- 2005-2007 - Eastmain Resources - Purchase of the project from Campbell Resources, VTEM, Prospecting, regional exploration.

- 2007-2019 - Eastmain Resources - Sporadic drilling, regional exploration, mapping, sampling, trenching. Surface geochemistry (soils)

|

| Geology | - Deposit type, geological setting and style of mineralisation.

| - In the Eastmain Gold Deposit, gold mineralization occurs in quartz veins with associated massive to semi-massive sulphide lenses/ veins and silicified zones associated with a deformation corridor.

- The mineralized zones are 3 m to 10 m thick and contained in a strongly deformed and altered assemblage (Mine series) consisting of felsic, mafic and ultramafic rocks.

- Mineralized quartz veins and lenses show a variable thickness between 10 cm and 13 m, and sulphide contents average 15% to 20% in the mineralized quartz veins and sulphide lenses. In order of decreasing abundance, sulphides consist of pyrrhotite, pyrite, and chalcopyrite, with minor sphalerite, magnetite and molybdenite. Visible gold occurs in the mineralized quartz veins as small (<1 mm) grains associated with quartz and (or) sulphides in the A, B and C Zones.

- At E Zone, mineralization is also associated with a Tonalite intrusion. Mineralisation occurs at the upper sheared contact between the Tonalite and the overlying ultramafic units. Mineralisation also occurs in veins within the tonalite and in zones displaying silica-sericite-albite alteration.

|

| Drill hole Information | - A summary of all information material to the understanding of the exploration results including a tabulation of the following information for all Material drill holes:

- easting and northing of the drill hole collar

- elevation or RL (Reduced Level - elevation above sea level in metres) of the drill hole collar

- dip and azimuth of the hole

- down hole length and interception depth

- hole length.

- If the exclusion of this information is justified on the basis that the information is not Material and this exclusion does not detract from the understanding of the report, the Competent Person should clearly explain why this is the case.

| |

| Data aggregation methods | - In reporting Exploration Results, weighting averaging techniques, maximum and/or minimum grade truncations (eg cutting of high grades) and cut-off grades are usually Material and should be stated.

- Where aggregate intercepts incorporate short lengths of high grade results and longer lengths of low grade results, the procedure used for such aggregation should be stated and some typical examples of such aggregations should be shown in detail.

- The assumptions used for any reporting of metal equivalent values should be clearly stated.

| - No analytical results reported

- Qualitative observations only

|

| Relationship between mineralisation widths and intercept lengths | - These relationships are particularly important in the reporting of Exploration Results.

- If the geometry of the mineralisation with respect to the drill hole angle is known, its nature should be reported.

- If it is not known and only the down hole lengths are reported, there should be a clear statement to this effect (eg 'down hole length, true width not known').

| - The exact geometry of the system is still not completely known.

- Drillhole orientation and known structural setting suggest that drillholes intersected mineralisation close to perpendicularly meaning that downhole intervals are believed to be close to true width/thickness

|

| Diagrams | - Appropriate maps and sections (with scales) and tabulations of intercepts should be included for any significant discovery being reported These should include, but not be limited to a plan view of drill hole collar locations and appropriate sectional views.

| - See figures in the body of text

|

| Balanced reporting | - Where comprehensive reporting of all Exploration Results is not practicable, representative reporting of both low and high grades and/or widths should be practiced to avoid misleading reporting of Exploration Results.

| - No analytical results released in this announcement.

|

| Other substantive exploration data | - Other exploration data, if meaningful and material, should be reported including (but not limited to): geological observations; geophysical survey results; geochemical survey results; bulk samples - size and method of treatment; metallurgical test results; bulk density, groundwater, geotechnical and rock characteristics; potential deleterious or contaminating substances.

| - Benz conducts systematic BHEM of each hole drilled as well as BHEM surveying of historical holes.

- BHEM identified over 150 in-hole and off-hole conductors coincident or not with drilled mineralization.

|

| Further work | - The nature and scale of planned further work (eg tests for lateral extensions or depth extensions or large-scale step-out drilling).

- Diagrams clearly highlighting the areas of possible extensions, including the main geological interpretations and future drilling areas, provided this information is not commercially sensitive.

| - Benz Mining is currently conducting a 50,000m drilling campaign which started in January 2021, approximatively 35,000m has been executed with c.15,000m remaining

- This drilling is conducted alongside regional FLEM surveys (TMC Geophysics)

- All new holes will be surveyed by BHEM as well as a selection of historical holes.

|

To view the source version of this press release, please visit

MENAFN20102021004218003983ID1103007010